VTT works on several objectives of the CIMPA goal of value retention of end-of-life multilayer films with a particular focus on tuning of the properties of multi-layer recyclates using a novel pilot recycling line (VAREX) with in-line adaptive rheology control and additivation.

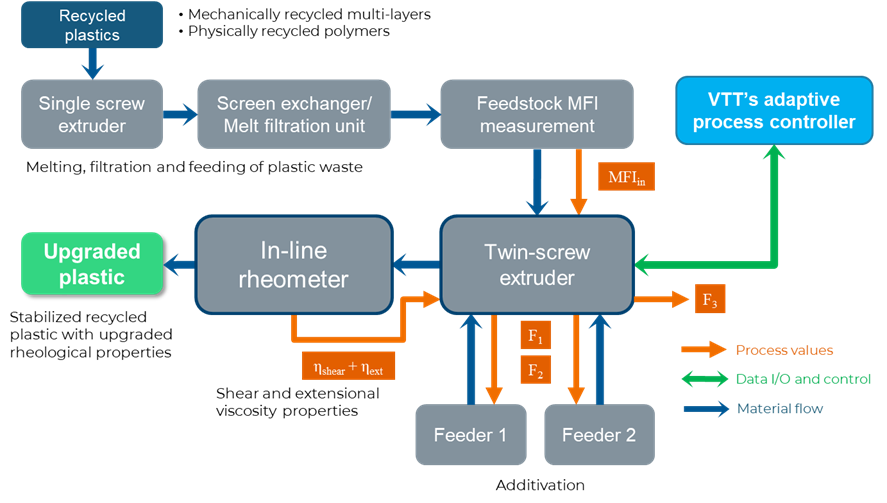

VTT develops an advanced compounding & mechanical recycling line with adaptive in-line property control capabilities aiming for stabilizing and upgrading the rheological and final properties of recycled multi-layer and multi-material plastics. The VAREX concept is based on smart reprocessing of recycled thermoplastics in a tandem extruder set-up where fundamental properties—such as the viscosity behavior of the plastic melt—are measured continuously in-line, allowing adaptive additivation and property upgrading of the recyclates to be performed. By upgrading the rheological properties of recycled materials to match the specifications for conversion, together with counteracting the detrimental effects of feedstock quality variations and polymer degradation by smart additivation, can provide significant increase in recycling rates and enhance the circularity of plastic packaging.

VTT’s pilot-scale VAREX extrusion line is depicted in Figure 1. In the first step, the recycled plastic is fed into a single screw extruder where it is melted and thereafter filtered to remove unwanted impurities such as metals, dirt or other non-melting components which can otherwise have a detrimental effect on the plastic quality. After the filtration step, the melt-flow properties of the recycled plastic (such as melt-flow index, MFI, or melt viscosity) are measured continuously in-line, providing insight into the rheological behavior of the recycled material. After this stage the recycled plastic melt is directed to a twin-screw extruder where the adaptive additivation takes place by additional material feeding. These additives can include for example process stabilizers, viscosity modifiers or virgin polymer, depending on the type and quality of the recycled plastic being processed. Finally, the melt viscosity of the upgraded plastic compound is measured in-line at the output section of the extrusion line before material pelletizing for conversion. In this scheme, the in-line viscosity instrumentation combined with VTT’s in-house developed soft-computing and process control algorithms allows smart controlling of the material composition and rheology for a wide selection of starting materials.

In CIMPA project, VTT is developing and up-scaling the VAREX in-line rheology control process from TRL 3-4 to TRL 5, and applies the VAREX pilot line for both mechanically and physically recycled multi-layer plastics, where some of the key challenges to be tackled include:

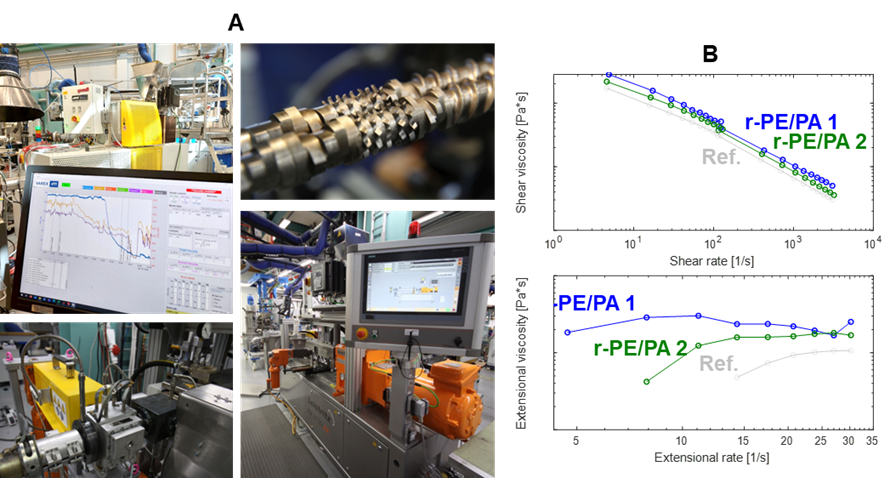

Figure 2 presents the VAREX pilot extrusion line at VTT and exemplifies in-line viscosity measurement for various recycled PE/PA based formulations.

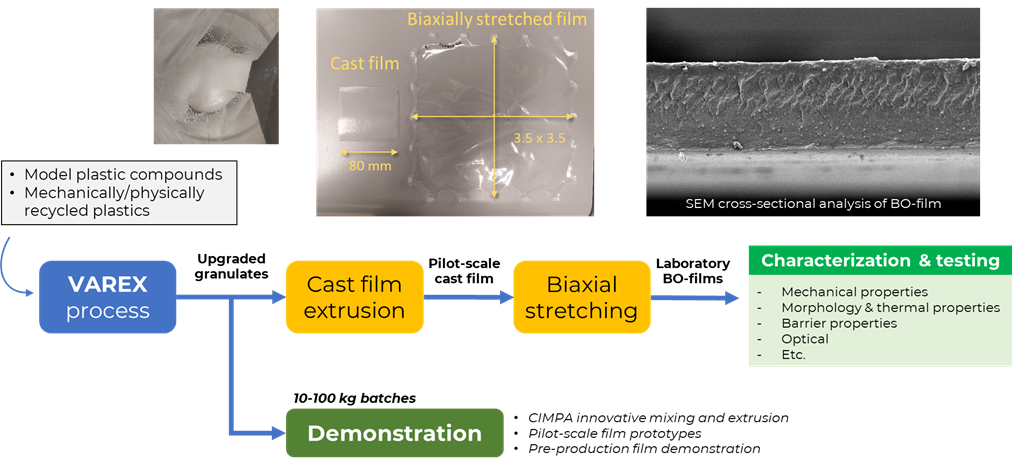

As a part of the development in the CIMPA project, VTT investigates the effects of recycling and recompounding processes on the properties (e.g. morphological, functional, thermo-mechanical and ageing) of multi-layer recyclates to verify process development along the CIMPA value chain. Moreover, VTT is also contributing to the testing, characterization and optimization of various lab-, pilot- and pre-production-scale film prototypes being produced during the project using model compounds and upgraded recyclates (Figure 3). For instance, laboratory-scale biaxial orientation of films will be tested and evaluated by VTT in order to verify e.g. enhancement of film barrier properties using novel extensional mixing technology developed by IPC (METEOR) for morphology control of immiscible polymer blends. The optimal film processing parameters are sought and are to be utilized in subsequent pilot and pre-production phases in CIMPA.