TNO works on 3 different aspects of the CIMPA goal of value retention of end-of-life multilayer films. These aspects tie together to create a better picture of the feasibility of the CIMPA solutions.

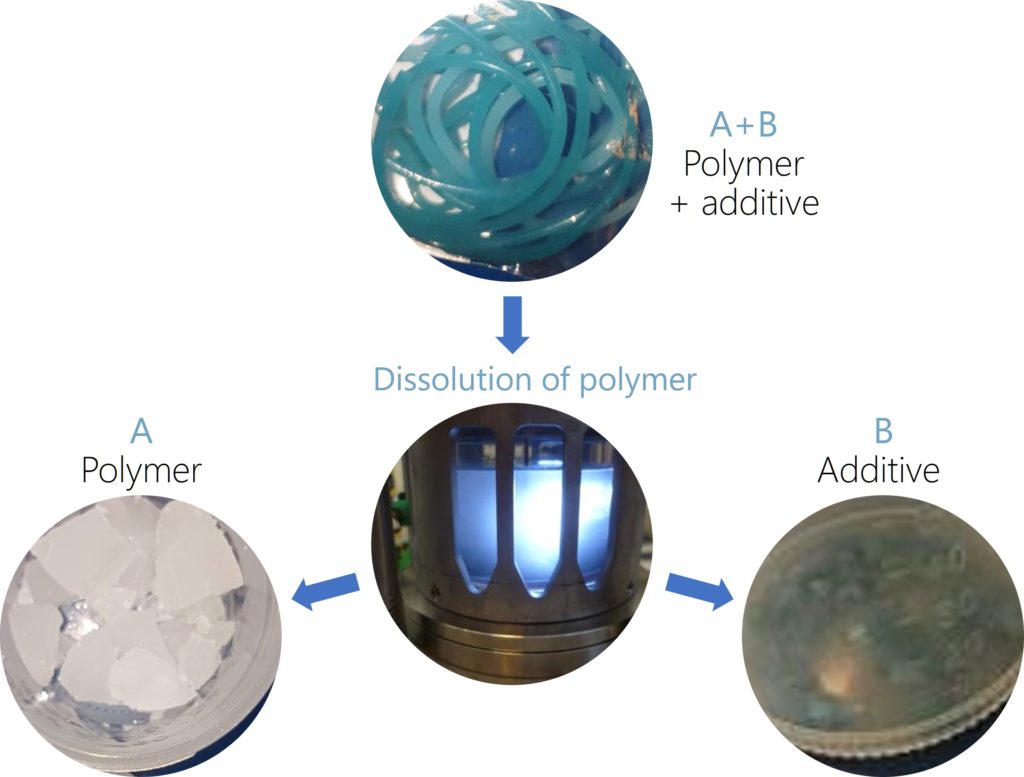

In Delft, TNO develops a physical recycling technology for waste plastics, the TNO Möbius technology. The basic concept is depicted in Figure 1. This technology is based on using a single low-boiling solvent to dissolve the target polymer under superheated conditions. Then impurities and additives are removed and the clean polymer precipitated by flash evaporation or by an addition of second solvent.

One of the key advantages of operating with a low viscosity solution is that this enables filtration and sorption for additive and/or impurity removal and recovery. The dissolution process allows for an energy efficient solvent recovery. To execute the process, a dedicated experimental set-up has been developed and is depicted in the Figure 2.

It is important to note that physical dissolution based recycling fundamentally differs from mechanical and chemical recycling. The physical recycling selectively recovers high quality polymers (polyolefins, PO, in case of CIMPA) which then represent only part of the original input waste stream. The remaining non-PO polymers and additives are separated and can be valorized as well. In mechanical recycling, the composition of the input basically only be changed by removing volatiles and/or addition of recompounding additives. In complex multimaterial systems and/or highly contaminated stream, this leads to a decrease quality of the recyclate. Chemical recycling, not studied in CIMPA, breaks chemical bonds and therefore recovers monomers or chemical building blocks as opposed to polymers.

Figure 3 presents results of a selective recovery of polypropylene (PP) from a multi-layered metallized packaging material. The PP fraction of the feed material was recovered with a high purity and a good yield.

As part of the development in the CIMPA project, TNO is in the process of upscaling the Möbius dissolution technology from TRL3-4 to TRL5. The TRL5 laboratory pilot scale facility will be used to demonstrate the dissolution-based recovery process in capacity to produce kg scale batches of recovered polyolefins after dissolution.

To assess the impact of the two recycling technologies in CIMPA, one of the TNO groups in Utrecht also performed a Life cycle assessment (LCA) screening of a PET-PE foil. This LCA was applied to both the recycling steps of the TNO dissolution and extensional mixing technology developed by IPC (METEOR). METEOR is used to control the morphology of immiscible polymers. During the process, shear rate, extensional flow, ratios of additives and polymers will be adjusted in order to develop best controlled morphologies between lamella and fibril.

The result of the Life cycle assessment screening showed the potential decrease in global warming potential (GWP) of 24% by using CIMPA technology for mechanical recycling (inclusion of METEOR technology) However, using the dissolution-based technology less improvement was observed. The latter originates from an effective lower material efficiency of the dissolution technology as it is assumed that only the PE fraction is recycled. Recycling the PET fraction can provide additional improvements in the total material efficiency and reduce the environmental impact. Moreover, currently it is assumed that both routes will create similar product quality. The equivalent quality of the recycled product is a parameter that can impact the results and needs to be confirmed experimentally.

The influence of the electricity consumption of the routes was also assessed. In the current scenario, using six impact assessment categories (particulate matter formation, terrestrial acidification, freshwater eutrophication, terrestrial ecotoxicity, human carcinogenic toxicity and mineral resource scarcity) it is another factor which leads to higher environmental burdens. Using a future (2050) model for electricity grid mix and recycling rate, the environmental performance is improved whereby a 25 – 36% decrease in GWP was achieved. The electricity grid for the 2050 scenario contains a larger fraction of renewables and thus lower GWP.

Finally, TNO is involved in food contact assessment and compliance to agricultural standards. This task is performed at the Particle Expertise Centre (PEC) in Utrecht, where a broad range of analytical equipment is present for method development and analysis. The works focusses on the detection of Non-intentionally added substances (NIAS). NIAS are a broad range of potentially harmful chemicals that originate from for instance breakdown of compounds in the foil due to use or processing. If present in food contact materials, these NIAS can migrate into the food which could be harmfull.

Currently, a qualitative screening with direct thermal desorption-gas chromatography (DTD-GCMS) is being performed on both non-treated and decontaminated samples. In collaboration with IPC and Paprec, who will screen the same samples, TNO will compile a list of NIAS compounds. Methods based on DTD-GCMS and additional techniques will be developed to quantify these compounds in materials from the demonstrator tasks later on in CIMPA.

In conclusion, TNO is happy to be part of CIMPA in the different ways described above and thus contribute to the value retention of end-of-life multilayer films.